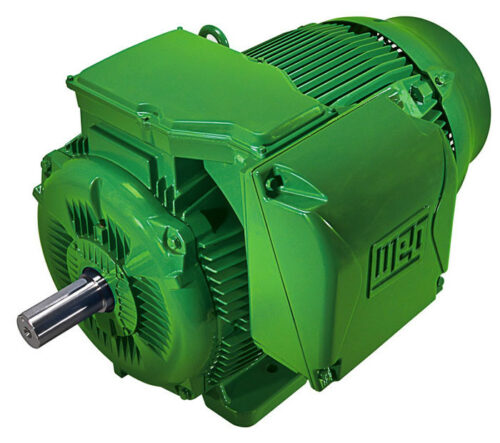

W50 motors offer not only excellent performance, but comply with the strictest efficiency and safety criteria in the most severe applications. W50 provides low vibration levels, versatility and reduced maintenance.

W50 Industrial Motor – Low Voltage

Description

Standard Features

- Rated output: 75kW to 1000kW

- Number of poles: 2 to 12

- Frame sizes: 315H/G to 450J/H

- Frequency: 50 or 60 Hz

- Voltage: 380 to 690V

- Service factor: 1,00

- Insulation class: F

- Degree of protection: IP55

- Mounting: B3

- Cooling method: TEFC – Totally enclosed fan cooled (IC411)

- Frame, endshields, fan cover and terminal box material: FC-200 cast iron

- Shaft material: AISI 4140

- Thermal protection:

- Windings: Pt-100 3 wire, 2 per phase

- Bearings: Pt-100 3 wire, 1 per bearing

- Grease lubricated ball bearings

- Bearing seal: Taconite labyrinth

- Vibration Level: Grade A according IEC 60034-14

- Lubrication: Mobil Polyrex EM Grease

- Painting plan: C5 (I and M) – High†Durability according ISO 12944

- Color: RAL 5009 (Blue)

- Dual Voltage Space Heaters

- Automatic drain plug

Optional Features

- Other mounting configurations: B35, V1, V5, V6, etc.

- Degree of Protection: IP56, IP65, IP66

- Cooling method: TEBC – Totally enclosed blower cooled (IC 416)

- Surrounding muffler

- Service factor: 1.15

- Bearings:

- Sleeve bearings

- Insulated drive end bearing for inverter duty applications

- Cylindrical roller bearing

- Shaft grounding brush

- Seal: INPRO/SEAL

- Vibration level: Grade B according IEC 60034-14

- Bearing and winding thermal protection: thermistors or thermostats

- Cable glands

- Drip proof canopy for shaft down applications

- Internal tropicalized painting

- Encoder

- Suitable for VFD applications

- Main terminal box in welded steel

- Additional terminal box: For Y†connection with access to the neutral terminal

- Non-contact / contact thermometer with gauge

- Stainless steel fasteners

Dedicated W50 lines

The W50 motors also feature a number of definite purpose versions, developed to meet specific industry and application requirements, whilst maintaining the need to provide the best solution for the customer.

W50Xn

With safety being of paramount importance, WEG developed the W50 Non-Sparking (Ex nA) motor line to operate in hazardous areas. This type of protection is applied to electrical equipment which does not cause ignition of an explosive atmosphere under normal operating conditions.

- Suitable for operation in IEC hazardous areas classified as Zone 2, Group II, Temperature class T3

- Compliance with NEC standard requirements regarding hazardous areas, such as Class I, Division 2, Groups B, C and D, Temperature Class T3

W50 IEEE 841

The W50 IEEE841 motors are specially suited for Pulp & Paper mills, Steel mills, Petrochemical Plants and diverse demanding applications requiring severe duty long life motors.

- Internal anticorrosive painting

- Guaranteed foot flatness to within 0.005â€

- T-type open drain made of stainless steel

- INPRO/SEAL bearing seal

W50 API 541

The W50 API 541 line was specially developed in accordance with the requirements of the American Petroleum Institute, the World reference in the standardization of equipment for the oil industry.

- Certified for ambient temperatures up to 60 °C

- Copper rotor

- Sleeve bearings

- Maximum Is/In of 6.5

- Stainless steel fasteners